Precise to the full stroke

Guth overflow valves are used to relieve pressure in closed systems or to limit the delivery pressure in conventional pump circuits. As soon as the supply pressure exceeds the set value, the valve opens and the escaping medium can be released outside in a controlled manner or returned. A flow-optimised plate geometry ensures precise opening and closing behaviour as well as high flow capacity.

The opening pressure can be adjusted by means of a hexagonal head. If the adjustment range of the drive is not sufficient, you can easily retrofit it and expand it with a larger drive. This is secured against unintentional adjustment. By means of pneumatic ventilation, the valves can be opened to full stroke, for example for CIP cleaning.

End position feedback or control heads can be mounted directly on the drive. Optionally, a purely pneumatic version is also available. Here, the closing pressure of the overflow valve is defined by a pressure superposition of the double-acting actuator . The setting of the overlay pressure or the response pressure is then carried out via an external filter pressure regulator.

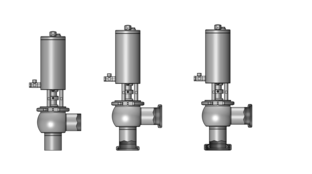

The Guth overflow valve range is available as a corner, T and ring line valve in the modular system. It fulfils all aspects of hygienic design.

![[Translate to Englisch:] Logo Guth Ventiltechnik](/fileadmin/user_upload/01_basic/Logo-Guth.png)