A true all-rounder

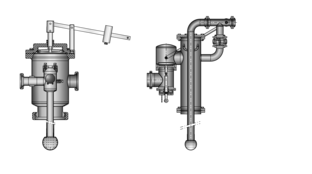

The Guth tank top unit TDAM is a combination of overpressure and underpressure protection, CO2recirculation and tank cleaning. The cost-effective design with only a single DIN connection to the tank makes an expensive tank top plate with various connections superfluous.

The overpressure protection through a component-tested, pneumatically actuated safety valve belongs to the numerous functions of the Guth tank top units. If the container pressure exceeds the set opening pressure, the valve opens automatically. An optional weight or spring-loaded vacuum valve, which opens if the set opening pressure is not exceeded, provides protection against under-pressure when the tank is emptied. The vacuum valve is also available with spray protection and pneumatic elevation for cleaning.

Also a CO2return, degassing, exists. The gases produced by the process are drained from the tank in a controlled manner by the gas recirculation integrated in the switching valve.

The interior of the tank can be cleaned by the connection of a spray nozzle or jet cleaner. The switching valve ensures that the cleaning agent is escorted directly to the tank cleaning device. Small spray nozzles in the tank top unit guarantee effective inner-cleaning of the product-touched surfaces, with minimum cleaning agent consumption. Safety and vacuum valves are also cleaned from the inside (CIP).

Additional process equipment, such as for example bunging valves, measuring instruments, attachments or other fittings, can be installed in the connection piping.

![[Translate to Englisch:] Logo Guth Ventiltechnik](/fileadmin/user_upload/01_basic/Logo-Guth.png)